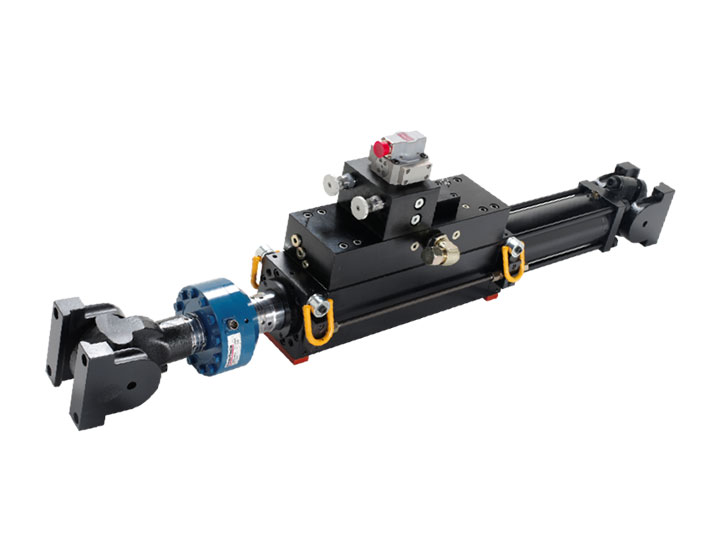

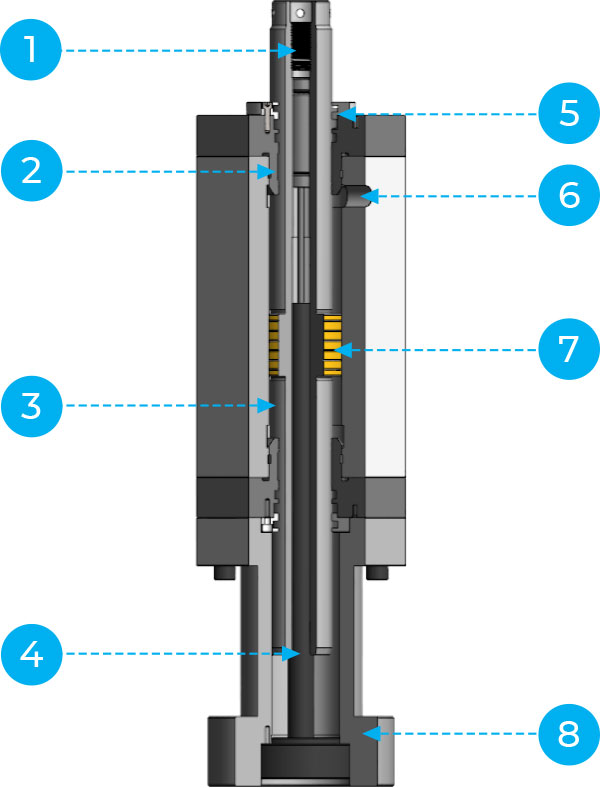

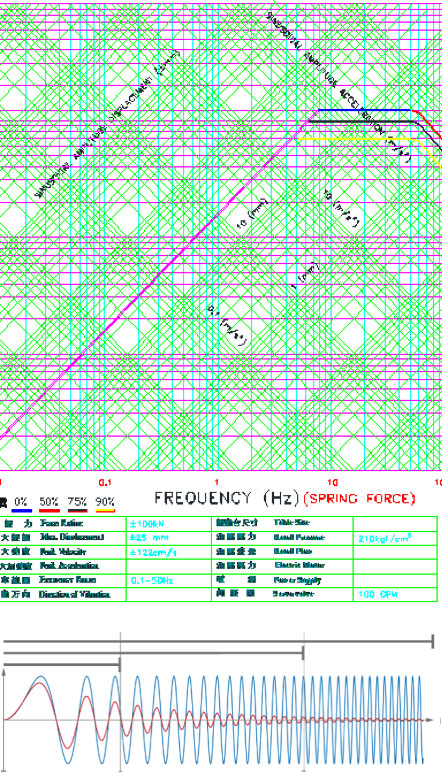

伺服液壓缸是電液伺服系統中的液壓執行元件,通過它將液壓能轉換成機械能。伺服油缸通常由伺服閥、作動筒、位移感測器和載荷感測器等部分組成一體,搭配閉環控制的伺服系統,既能控制大慣量、輸出功率大,又有高精度、高回應的性能,所以得到廣泛應用。

The servo hydraulic cylinder, is main component In electro-hydraulic servo system, that is composed of cylinder, servo valve, displacement sensor and force sensor(if necessary). The servo hydraulic cylinders are widely used with closed loop controlled system, that are used to perform high force and high response applications.